Technology & Services

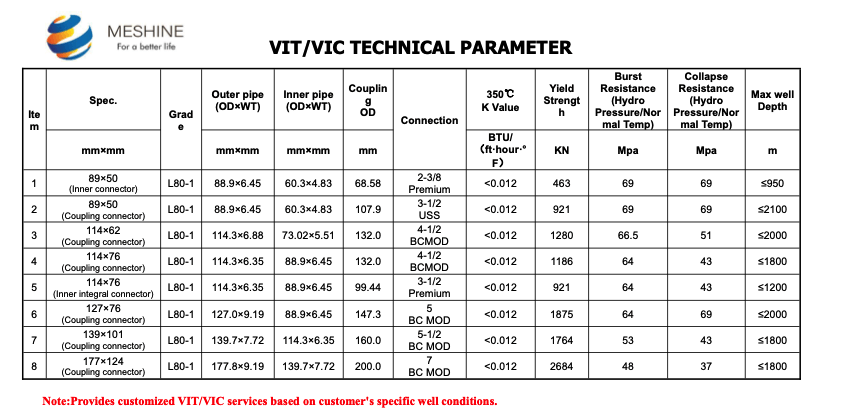

Oil Casing and Tubing Goods (OCTG)

Experience

- Specialised OCTG

- Won 5 year VIT contract from PDO

- Supplied & installed more than 30,000 VIT joints to PDO, OXY, PETROGAS & MEDCO, since 2011 - 2020

- 2021- Purchase order awarded for the supply of the 500 joint VIT - PDO

- 2022- 3 Years contract awarded for the supply of VIT to MEDCO

- 2022 - Purchase Order from PDO for the Supply of 1000 joints VIT

- 2023 - Purchase Order from PDO for the Supply of 500 joints upgraded VIT

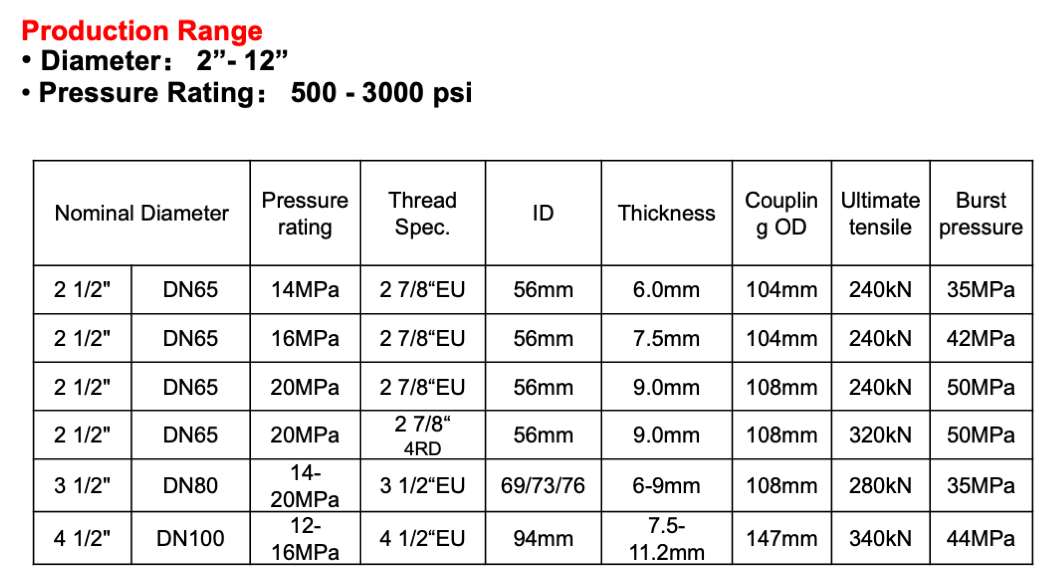

Glass Reinforced Epoxy (GRE) Down-hole Tubing & Casing

Experience

- Successfully supplied and installed > 1,000 joints of 3 1⁄2”, 4 1⁄2” solid GRE tubing and 10” GRE Casing for PDO - 2011 - 2020

- Supply of 3 1⁄2”, 4 1⁄2 “ 600 joints GRE downhole well tubing in 2021 to PDO

- PO awarded for the supply of 10" GRE Casing about 350joints from PDO -2022

- PO awarded for the supply of 3 ½" GRE Tubing for about 200 joints from Abraj Energy 2022.

- PO awarded for the supply of 4.5" GRE tubing for ESP Wells for about 84 joints as trial order to PDO-2023

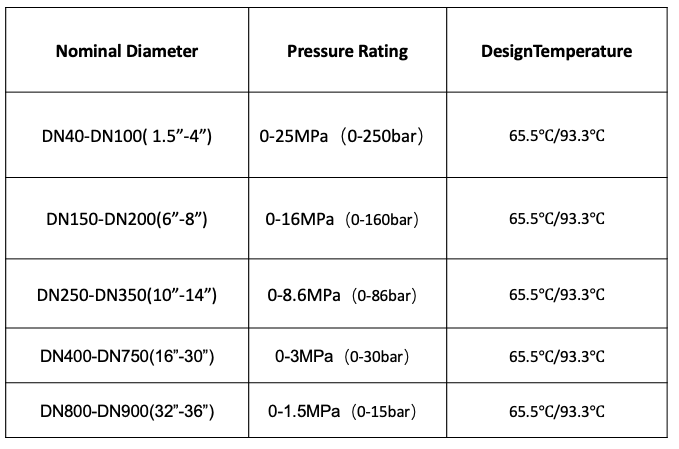

High Pressure Glass Reinforced Epoxy (GRE)

Experience

- Supplied HIGH PRESSURE and SOUR SERVICE GRE to PDO

PDO - Yibal Khuff Project - 2019

- 6” GRE pipe for oil gathering flow line

- Design temperature: 100 C / Design pressure: 10MPa

- Supply of GRE material, accessories and training material (trained subcontractors in installation)

PDO - Greater Birba Project - 2020

- High pressure and sour project

- Supply of GRE material, accessories and training material for 10 km

- Design temperature: 80 C / Design pressure: 12MPa

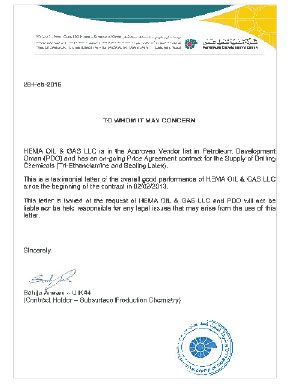

Chemicals

Products

- Drilling & Completion Fluid Additives

- Cementing Additives

- Stimulation Additives

Experience

- After PDO conducted several tests and evaluations on the chemicals supplied by COSL through Hema, a five year contract awarded for miscellaneous drilling fluids in Feb 2013

- We ensure the packaging and labeling adheres to the clients requirement and ensure the handling of the chemicals is made conveniently and securely

Well Heads

Conventional Wellhead

Technical Data Sheet

| WP | 2000Psi – 20000Psi |

| M/C | AA BB CC DD EE FF HH |

| T/C | -60 C-390 C -75 F-734 F |

| PSL | PSL1 PSL2 PSL3 PSL3G PSL4 |

| PR | PR1 PR2 |

| Medium | Oil Gas Mud |

Experience

- Ten years of globally supplying wellheads of various ranges

- Ranges 3k, 5k and 10k wellheads plus high temperature well heads for steam operations

- Supplied to Daleel Oman more than 5 years contract with good performance and track record

- Hema Energy contracted for the supply and installation of 5k and 10k wellheads to OXY

- Hema Energy got awarded a 2 year wellhead supply from OXY in June 2017.

- Hema Energy got awarded the work order for the supply of 3K wellheads to Petrotel 2020

- Hema Energy got awarded the work order for the supply of 10K wellheads From Petrotel 2022

- Hema Energy got awarded the work order for the supply of 4.5 inch tubing hanger BPV from petrotel 2023

- Hema Energy got awarded the work order for the supply of 10k wellheads to petrotel-2023

Vapor Corrosion Inhibitor Technology (VCI)

Application

- Successfully supplied and installed VCI to PDO 2020

- 2022-Supply & Apply of Volatile Corrosion Inhibitor for 5 external tanks(T-101, T-103, T-104, T-105, T-108) at MAF Tank Farm Area, PDO

- 2022- Supply & Apply of VPCI works for PDO Tank T-102 from STS

- 2023-Supply and apply of VCI work for PDO tank T-107.

- 2023- supply & apply of VCI work for PDO Tank 116/117.

- 2023- supply & apply of VCI work for OXY 5 tanks

Installation

- Installed PVC pipes

- Corrosion monitoring

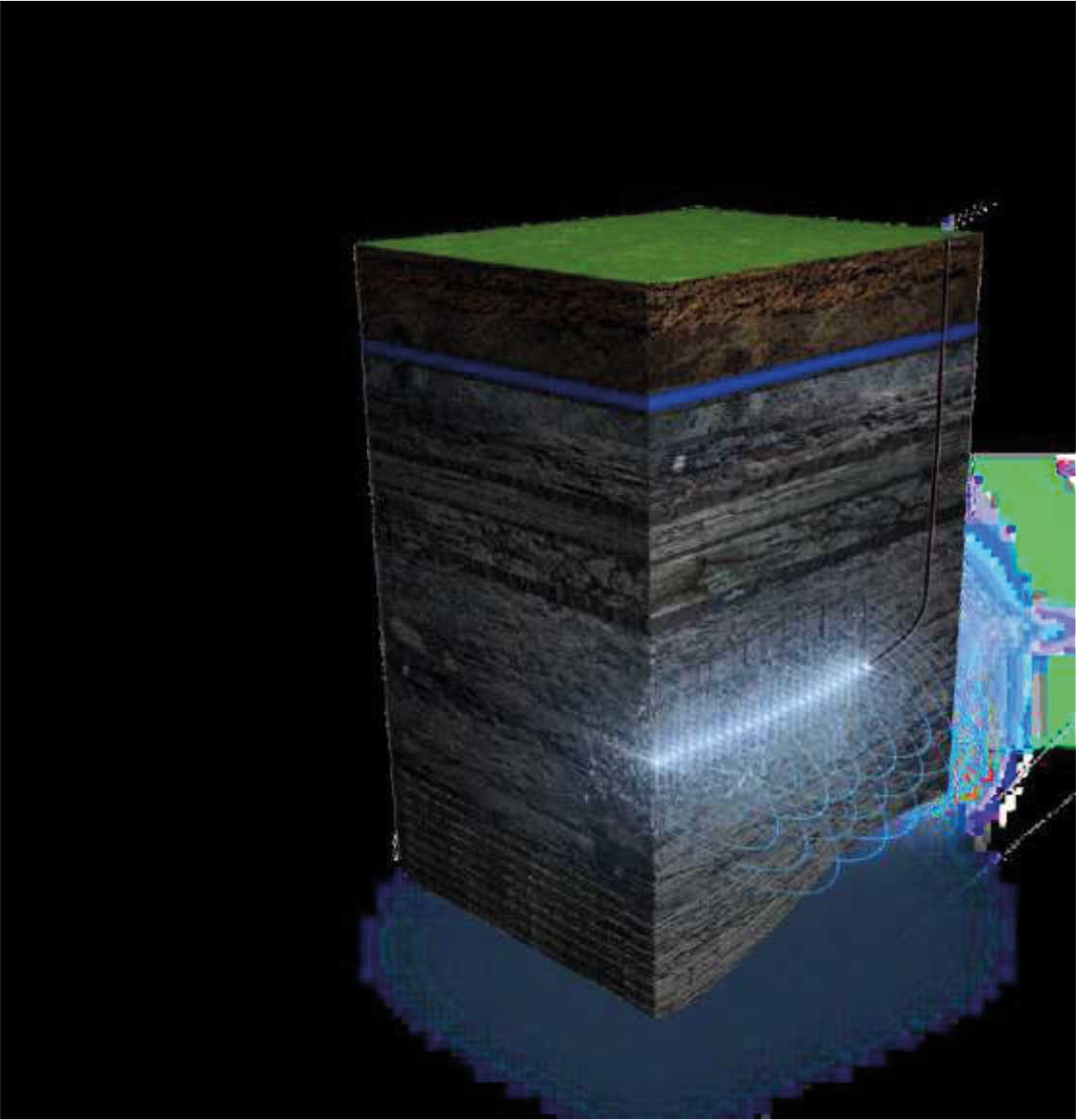

Well Stimulation Technology

Experience

- Trail order awarded from Petrogas for 2 wells - 2023

Long Lermgth Reinforced Thermoplastic Pipes (LLRTP)

Specification

- PDO Approved

- Qualified as per Shell DEP standard

- Corrosion – resistant, both inner and outer pipes are polymer layers with a design life of 20 years and long – term maintenance – free

- The inner wall is smooth, anti – fouling and low fluid resistance

- Savings on welding costs, flaw detection fees, replenishment fees, anti - corrosion fees, etc and construction procedures

- Recyclable and reusable, which can improve the economic benefits of the entire oil and gas field development and protect environment

- API 15S

- API 17J

Steam Generators

Specification

- Super Critical Steam Generators up to 360 bar injection pressure and 98% steam quality

- Critical success factor for any steam injection project is the high quality generation and injection of steam

- Maximum of 100 T/ hour units can be supplied

- Can provide both Mobile and Fixed units

- Can customize units to clients requirements

Steam Generators Oilfield Steam Boiler

- Steam Generators

- Oilfield Steam Boiler

- Steam Generators Rated evaporation (ton/h): 5-100

- Design pressure(Mpa):15,17.2,21,26

- Steam temperature(°C):354-390

- Steam dryness(%): 85 100

- Thermal efficiency (%): ≥90

- Combustion mode: oil/gas/the mixture of oil and gas

- Transport mode: Vehicle/Trailer mounted

Mobile Water Treatment Device

- Peridoical Water Production (m3):400

- Water Hardness: 0

- Oxygen Content (mg/L): <_0.007

- Water Use Rate(%): ≥90

- PH Value: 8-9

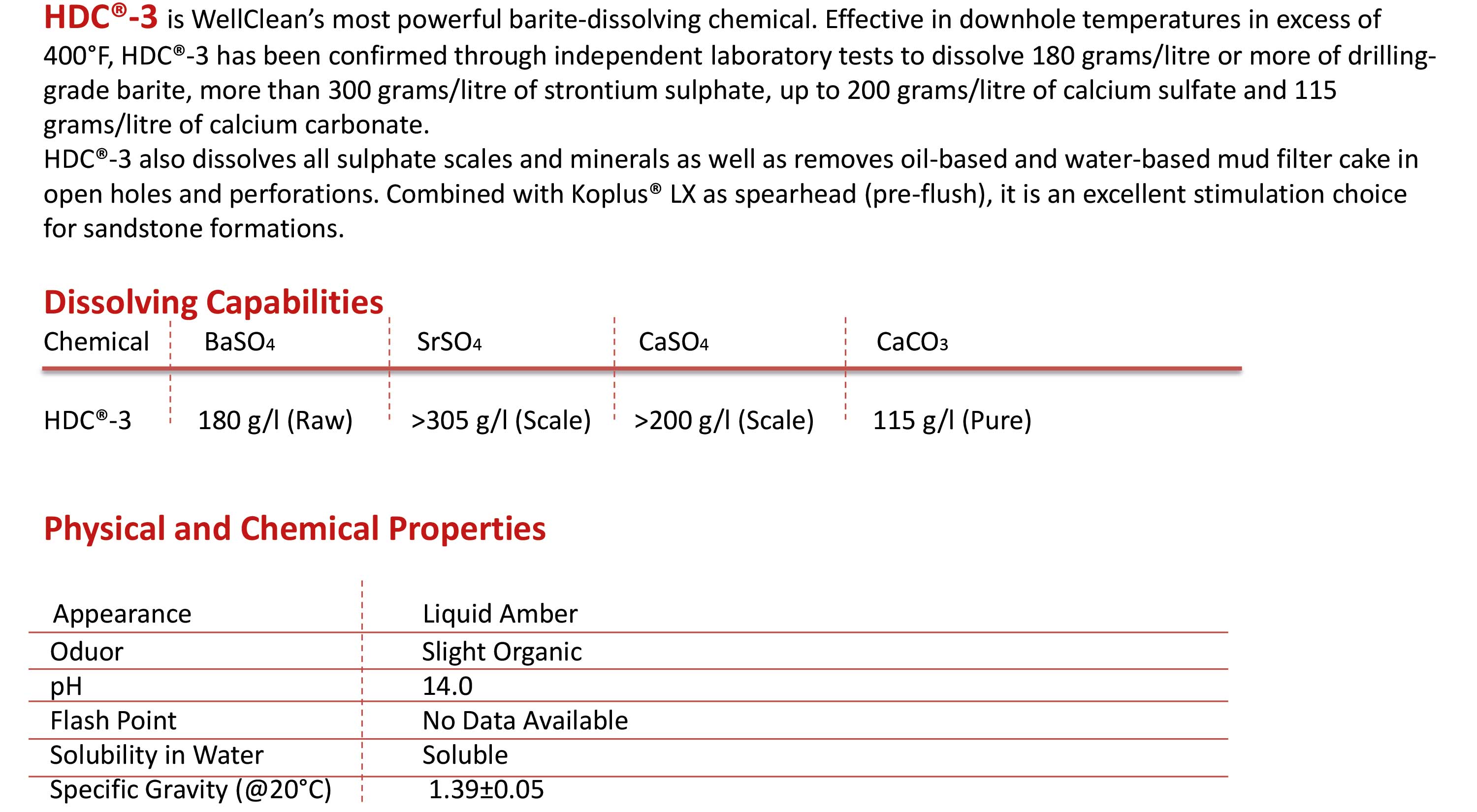

Wellbore Cleanup Solution

A premier independent providers of technology-enabled stimylation chemicals and wellbore cleanup solutions.

Technologies

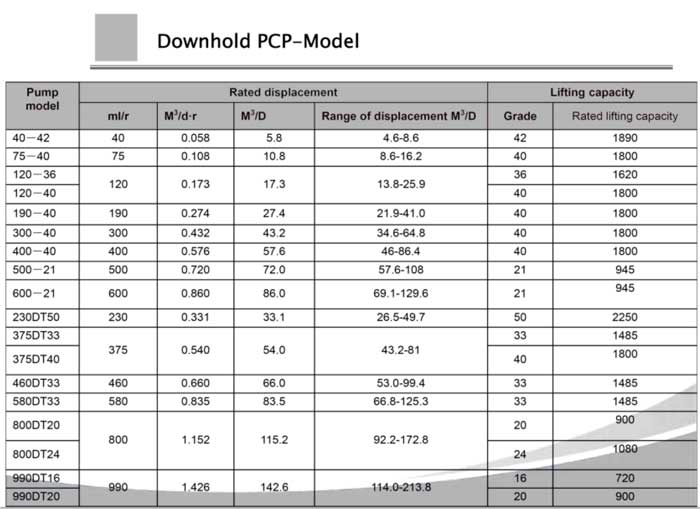

Progressive Cavity Pump (PCP)

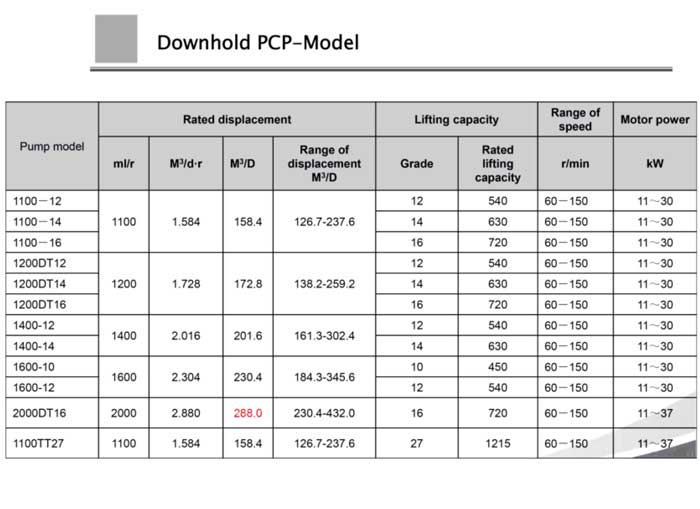

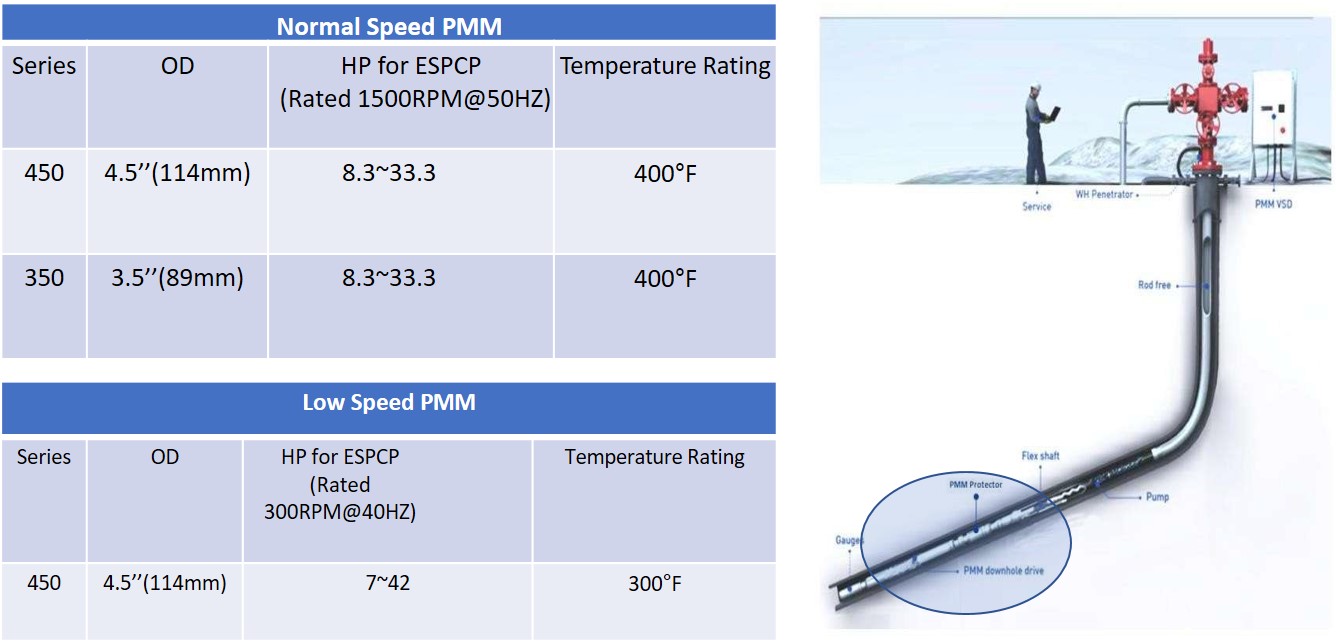

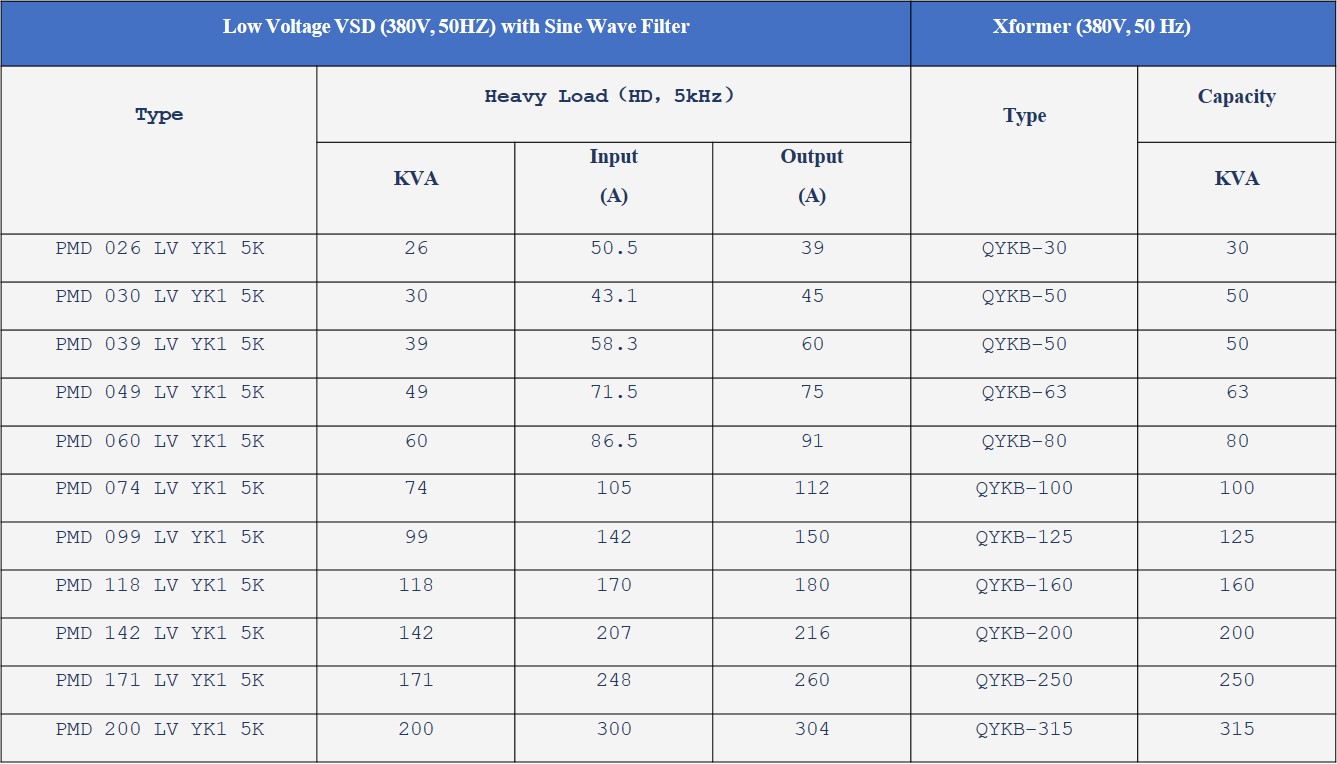

ESPCP System

ESPCP

- Rod free, tubing or coiled tubing - adapt to high deviation or horizontal well

- Completely eliminate the eccentric wear problem of rod and tubing

- Eliminate the potential surface leakage issue

- Eliminate the surface safety issue (no rotating components)

- Energy save - >25% efficiency improve

Direct driven by E3 Low Speed PMM

- PM Motor - Higher system efficiency (>15%) vs. IM Motor Gear box drive system

- Eliminate gear box concern

- High Torque Capacity (maximum 2021N.m) – without the gear box limitation

- Wider range of flowrate ( maximum 2000BPD) and lifting head (maximum 4000m with special pump)

Advanced Biochemical Innovation Solution Concept

Protein Surfactant complex (PSC) blind of Biosurfactant and syncretic surfactant to achieve following functions for Advanced IOR

Light oil application

- Alter wettability

- Lower IFT

- Eliminate water blockage

- Improve relative permeability

Heavy oil Application

- PSC mixing with solvent to create microemulsion to reduce viscosity and increase oil mobility in addition to light oil blind functions

Composite Material Utility Poles

Model and Specifications

- Φ190x12000mm

- Φ190x15000mm

Product Standards

- T/CEC 108-2016 Distribution network composite

Applications

- Mountainous areas, tidal flats, swamp areas; electric power rush repair

Product Characteristics

- Excellent mechanical properties, light weight, corrosion resistance, anti-aging, excellent electrical insulation properties, strong designability,excellent anti-skid properties, and strong hydrophobicity.

Fiberglass Continuous Sucker Rods

Fiberglass, as the main reinforcing material, is prepared by extrusion and pultrusion process.

Model and Specifications

- Φ22mm 、Φ25mm、 Φ28mm

Reference Standards

- SY/T 5029-2013 Sucker rods

Applications

- Corrosion wells, conventional oil wells

Product Characteristics

- Light weight —— energy saving corrosion resistance

- Eccentric wear

- Resistant —— longer service life

Application scheme of fiberglass continuous sucker rod

Conventional well corrosion protection applications

FRP continuous sucker rods should be used in conventional oil wells and corrosion wells with pump setting depth less than 2000m. Matching equipment: Oil pumps: Diameter: Ø38- Ø56mm Pumping unit: According to different diameters, 10-14 type pumping units are selected, and the stroke frequency are adjustable.

Large GRP Storage Tanks

GRP vessels are fabricated on site by filament winding, jetting molding, contact molding, etc. using fiberglass and its products as the reinforcing materials and resin as the base material.

Model and Specifications

- Diameter ≥ 4.5m;

- Capacity≥100m3;

- Can be designed and customized according to customers’ requirements.

Product Standards

- HG/T 20696 Technical Code of Reinforced Equipment for Chemical Industry HG/T 3983 Fiament Wound Glass-fiber Reinforced Thermosetting Resin Chemical Resistant Large Tanks Made on Site Applications

Product Characteristics

- High corrosion resistance, long service life;

- Light weight, convenient installation, low total costs;

- Smooth inner wall, not easy to wax and scale, saving maintenance costs;

- Never rusting, causing no secondary pollution to the medium;

- Anti-fouling and moth resistance, good wear resistance and strong designability;

- No need to transport, easy to install

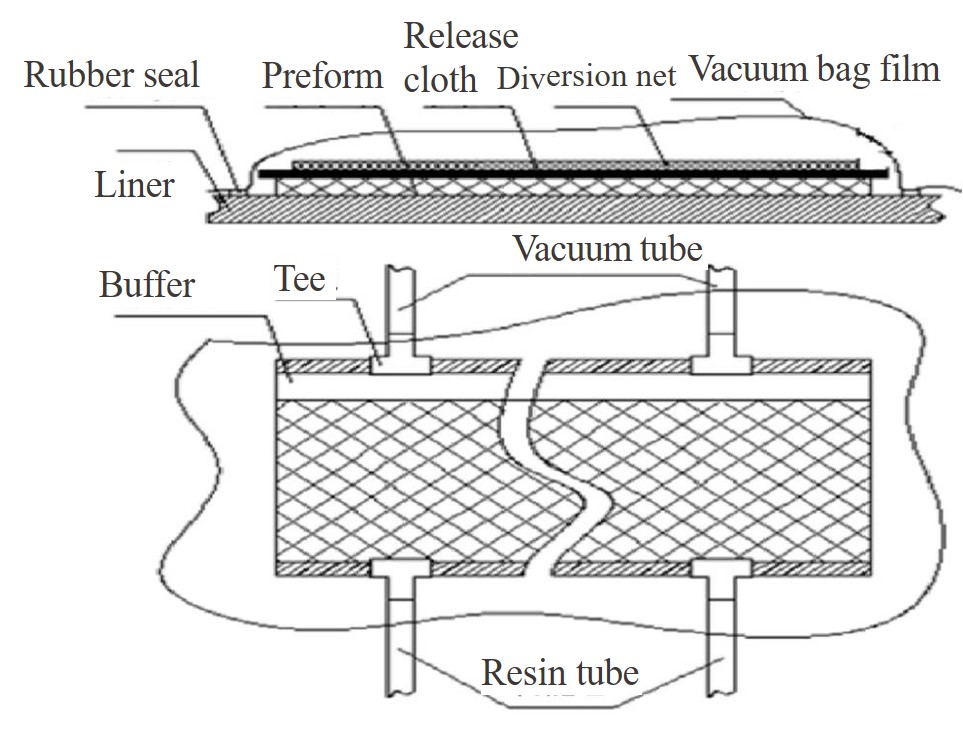

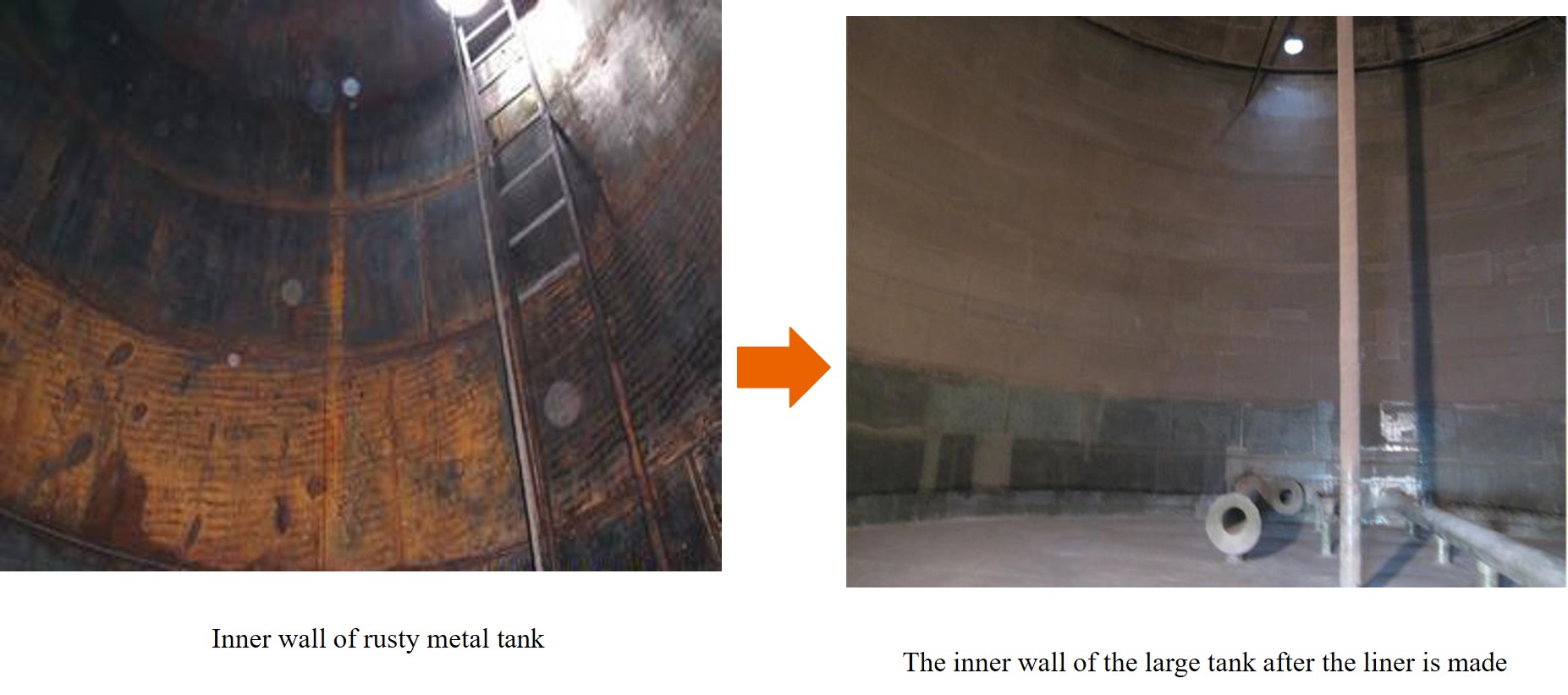

High-Strength Composite Material Liner

It is made by lining the inner wall of metal tanks with vacuum priming technology using fiberglass and its products as reinforcing materials and resin as the base material..

Model and Specifications

- Same as metal tank capacity; normal

- thickness≤4mm

- Pressure rating: atmospheric pressure

Product Standards

- Q/0502 SXD 010 High-strength Composite Material Liner for Vertical Steel Storage Tanks

- Q/SH1020 2409 Specification for ConstructionQuality

- Acceptance of Fiberglass Reinforced Composite Liner of Steel Vertical Storage Tank Applications

- Invention Patent No. ZL 2009 1 0016651.9

Applications

Suitable for anti-corrosion of new metal storage tanks, enhancement and anti-corrosion of old metal storage tanks.

Product Characteristics

- The strength of the high-strength composite liner is over 30% higher than that of hand lay- up (fiberglass reinforced plastic);

- Stable product quality;

- Less pollution in construction environment;

- Excellent adhesion to metal tank walls.